What Are the Different Thread Bar Types?

In the world of construction and engineering, the choice of thread bar can significantly impact the structural integrity and longevity of a project. With an array of options available, it becomes imperative to discern the subtleties between various thread bar types. In this comprehensive guide, we delve into the intricacies of different thread bar variants to empower you with the knowledge needed for informed decision-making.

Before we explore the nuances of various thread rebar types, it's crucial to grasp the fundamentals. A thread bar is a crucial component in construction, serving as a reinforcement element in concrete structures. Typically manufactured from high-strength steel, thread bars are known for their ability to enhance tensile strength, making them indispensable in various applications.

The Core Varieties: Exploring Different Thread Bar Types

1. Standard Thread Bars

Characterized by their simplicity and versatility, standard thread bars are the go-to choice for many construction projects. With a uniform threading pattern, these bars offer reliability and ease of installation.

2. High-Strength Thread Bars

When projects demand superior strength and durability, high-strength thread bars step into the spotlight. Engineered from specialized alloys, these bars provide exceptional tensile strength, making them ideal for heavy-duty applications.

3. Corrosion-Resistant Thread Bars

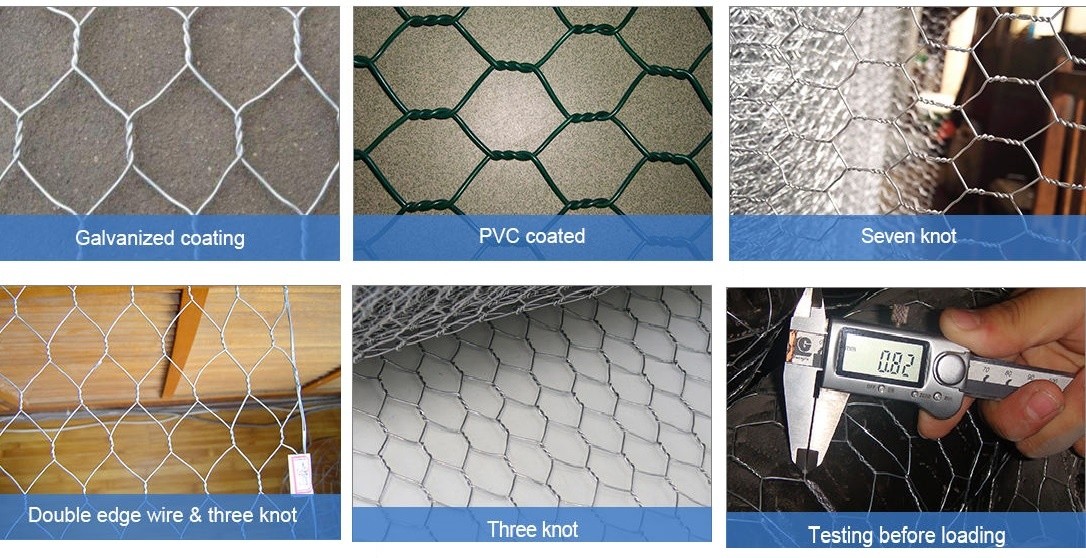

In environments prone to corrosion, such as coastal areas or structures exposed to harsh weather conditions, opting for corrosion-resistant thread bars becomes imperative. These bars are typically coated with protective layers to ensure longevity in corrosive settings.

4. Fully-Threaded vs. Partially-Threaded Bars

The threading pattern of thread bars varies, with some featuring full threading, while others opt for partial threading. Fully-threaded bars provide consistent strength throughout their length, while partially-threaded bars offer a balance between strength and flexibility.

Additional reading:How Much Pressure Can a 20k Butterfly Valve Handle?

What are the Problems with Gate Valve 20k?

What are the advantages of injection molding?

Solving Your Top SASE Tooling Questions

Unlock the Secrets to Choosing the Best Concrete Core Drill Bits

What Are OCTG Tubes?

Fiberglass Telescopic Pole: A Durable and Versatile Tool for Height Access

Selecting the Right Thread Bar: Key Considerations

1. Project Requirements

Before making a decision, carefully assess the requirements of your project. Consider factors such as load capacity, environmental conditions, and the specific structural demands to determine the most suitable thread bar type.

2. Material Composition

The material composition of a thread bar is pivotal. High-strength steel is a common choice, but depending on the project's demands, alloys or coatings may be necessary to enhance durability and resist corrosion.

3. Installation Ease

Different thread bar types come with varying installation complexities. Factor in the ease of installation, especially if time constraints are a concern for your project.

4. Budgetary Considerations

While quality should never be compromised, it's essential to consider budget constraints. Evaluate the cost-effectiveness of different thread bar types in alignment with your project's financial parameters.

Conclusion

In conclusion, the world of thread bars is diverse, offering a spectrum of options tailored to meet the unique demands of construction projects. From standard threaded rod to corrosion-resistant variants, each type serves a specific purpose in enhancing structural integrity. When choosing the right thread bar type for your project, meticulous consideration of project requirements, material composition, ease of installation, and budgetary constraints will pave the way for optimal outcomes.

Additional reading:Features and Benefits of Threaded Bar

Benefits of Using Tubular Knobsets in Your Home

The Most Precise Metal Casting: Achieving Unparalleled Accuracy in Manufacturing

Exploring Different Types of Cylindrical Lever Locks and Their Applications

Troubleshooting Residential Deadbolts

The Benefits of Using Threaded Bars in Structural Engineering

What Are The Key Design Considerations for Plastic Injection Molding?

30

0

0

Related Articles

Comments

All Comments (0)