Benefits and Applications of Conveyor LBP Chain

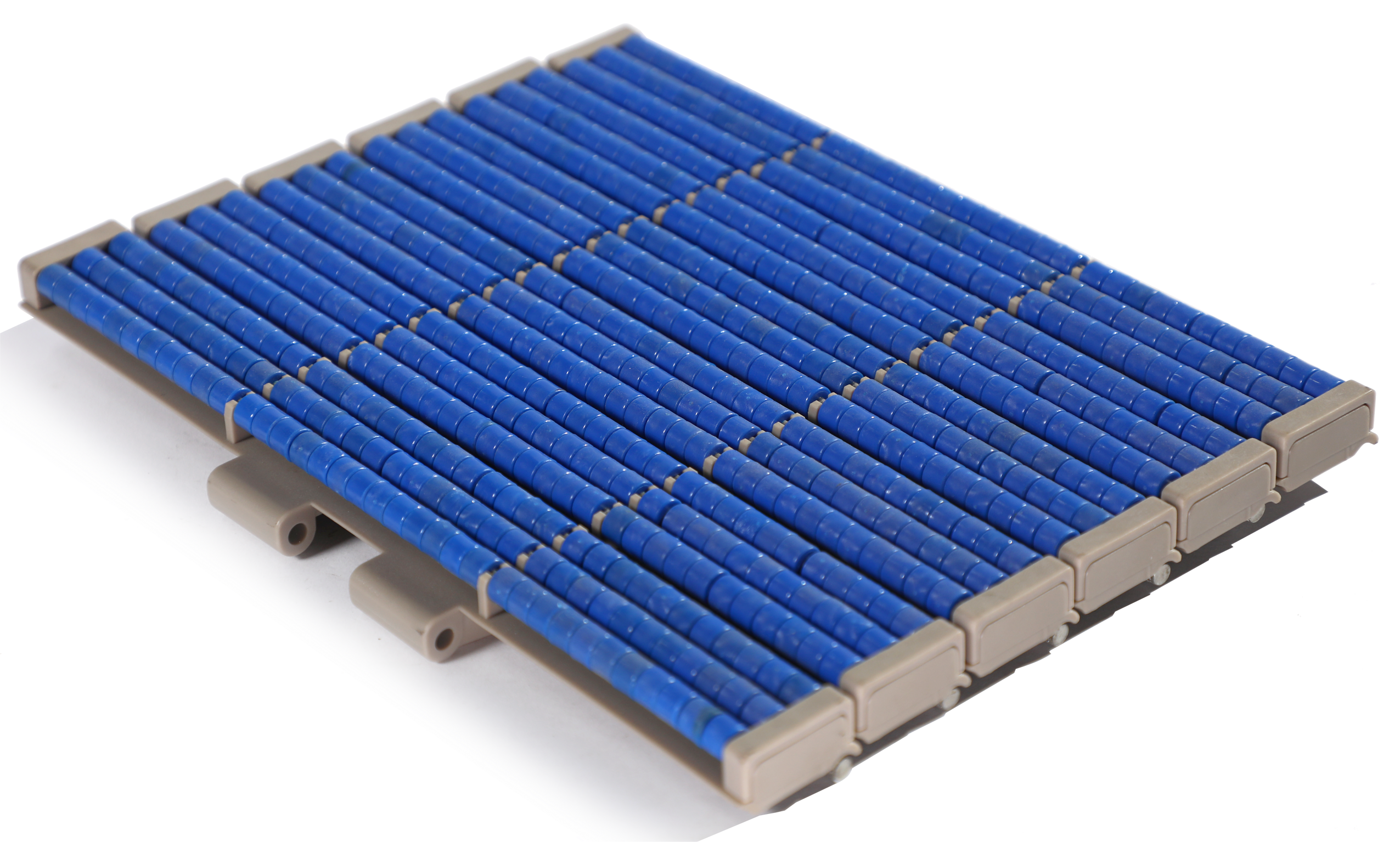

Conveyor LBP chains are innovative components designed to enhance material handling efficiency across various industries. These specialized chains significantly reduce back pressure, ensuring smooth and consistent transportation of goods, even under high-speed conditions.

Key Features of Conveyor LBP Chain

Low Back Pressure Technology

The LBP chain is designed to minimize friction between products during transportation. This crucial feature prevents potential damage and ensures seamless operations in conveyor systems.

Durable Construction

Constructed from high-quality materials, LBP chains are engineered to support heavy loads and resist wear and tear, promising long-lasting performance even under demanding conditions.

Modular Design

The modular design of LBP chains enables effortless customization, allowing easy integration into existing conveyor systems and improving overall operational flexibility.

Enhanced Product Stability

These chains ensure maximum stability during transport, effectively preventing items from tipping or shifting, thereby enhancing safety and efficiency in operations.

Applications of Conveyor LBP Chain

Food and Beverage Industry

LBP chains are predominantly utilized in the food and beverage sector, facilitating the smooth movement of bottles, cans, and various products, reducing downtime and boosting productivity significantly.

Pharmaceutical Industry

In the pharmaceutical sector, these chains are perfect for transporting delicate items, ensuring precise handling and maintaining the integrity of sensitive products.

Automotive Industry

Within the automotive assembly lines, LBP chains streamline the movement of components, optimizing operational efficiency while sustaining workflow consistency.

Packaging Industry

These chains are ideal for packaging lines, as they allow for the hassle-free transport of boxes and cartons without causing any damage to the products.

Benefits of Using Conveyor LBP Chain

Reduced Maintenance Costs

The robust design of Radius LBP chains minimizes wear and tear, which leads to lower maintenance requirements and costs over time.

Improved Operational Efficiency

With low back pressure and improved stability, LBP chains promote smoother workflows and enhance processing times, leading to increased productivity.

Versatile Applications

These chains are versatile, adapting seamlessly to various operational demands, from food processing to heavy industrial settings.

Product Safety

By effectively reducing back pressure, LBP chains safeguard products from damage, ensuring that quality standards are consistently upheld.

Conclusion

In conclusion, Conveyor LBP chains are vital components for efficient material handling across multiple industries. Their advanced features, durability, and versatility make them a worthwhile investment for improving both productivity and product safety. By incorporating LBP chains into your operations, you can achieve streamlined workflows and enhanced efficiencies.

77

0

0

Comments

All Comments (0)